Industry 4.0 and the industrial internet of things (IIoT) face a similar challenge when it comes to the exchange of data between operational technology (hardware and software that monitors and controls physical devices) and information technology (systems handling the flow of information/data between applications) even within a single enterprise. Open Platform Communications United Architecture (OPC UA) is an open interface standard for industrial automation/communication that has been adopted by Industry 4.0 and IIoT as an interoperable protocol for distributing data streams to consuming edge applications.

While OPC UA has evolved to be a secure and reliable protocol for exchanging data from process control systems to applications in all levels of the enterprise, recent trends in IIoT and Industry 4.0 have introduced performance bottlenecks as microservice applications are becoming more widely distributed across various on-premises and multi-cloud environments. As requirements for speed and scale are evolving in the enterprise, a solution for efficient data distribution among large numbers of consuming applications on the edge, cloud, or hybrid cloud is needed now more than ever.

Data Exchange Between OT and IT in Distributed Industry 4.0 or IIoT Systems

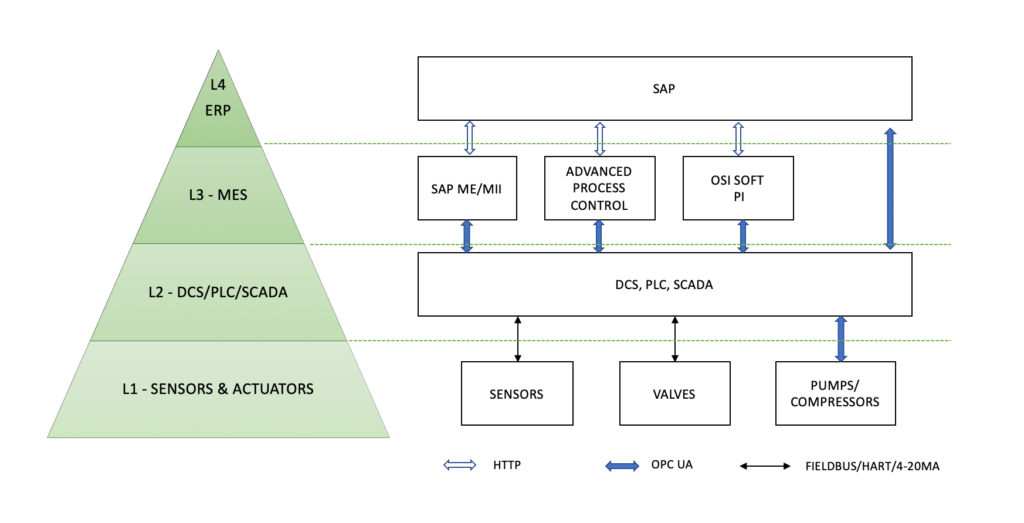

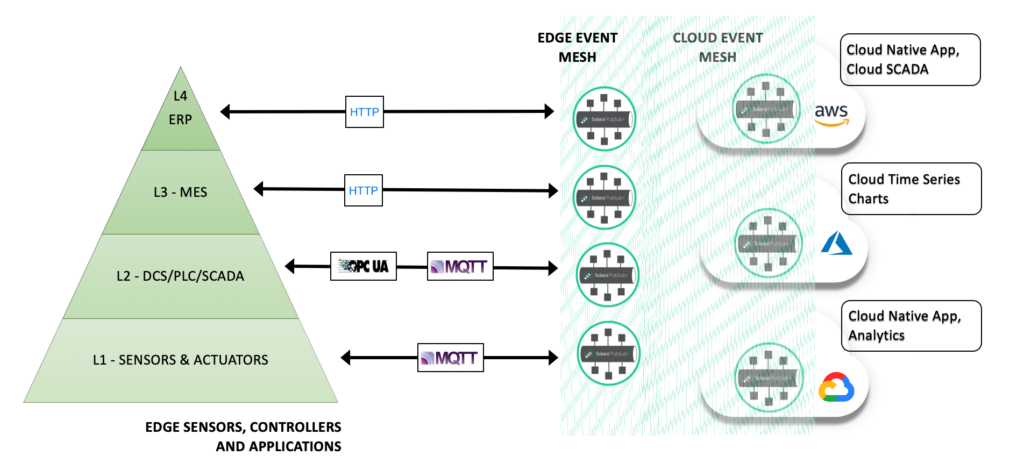

Data exchange between OT and IT systems in continuous, and discrete process manufacturing industries – such as oil and gas, energy production, chemical plants, car manufacturing, etc. – follow guidelines specified by ISA/ANSI 95. ISA/ANSI 95 standardizes automated interfaces between enterprise applications and industrial control systems, and defines four levels into which technology and business processes fit:

Level 0: Physical Processes

The actual physical manufacturing processes being monitored and controlled

Level 1: Sensing and Manipulating the Physical Processes

The equipment like sensors, valves, and actuators that can sense changes and impose actions on the physical processes

Level 2: Monitoring and Controlling the Physical Processes

The data ingestion, compute and intelligence responsible for real time process control executed by sophisticated on-prem/edge systems such as programmable logic controllers (PLC), distributed control systems (DCS), supervisory control and data acquisition systems (SCADA), etc. Level 2 systems exchange data with systems that make up Level 3.

Level 3: Advanced Process Control (APC), Manufacturing Execution Systems, etc.

These systems optimize production yield, plant operations, maintenance, etc., feeding on process data from level 2 systems. Level 3 systems include the manufacturing execution system (MES) that track the transformation of materials into finished products.

Level 3 systems exchange data with systems in Level 4.

Level 4: Enterprise Planning & Business Operations

The enterprise resource planning (ERP) system is often what makes up level 4 in enterprises. It is responsible for tracking, analyzing, and controlling broader business level functions including supply chain, logistics, warehousing, finance, HR, etc. ERP systems not only enforce operational goals and boundaries to process control systems (such as APC, DCS, PLC), but also get near real-time business feedback on raw material and product inventory levels, plant capacity, and operational data as part of optimization of the holistic business to enhance product/service quality, agility, and customer experience.

Level 4 systems are often integrated and exchange data with systems in level 2 and level 3.

How OPC UA Fits In: The Benefits and Tradeoffs

With the evolution of open standards in Industry 4.0 and IIoT process control, most DCS/PLC vendors have adopted OPC UA as an interoperable protocol for distributing data streams to consuming edge applications like SCADA, PI, Historian, Alarm Logger, ERP etc.

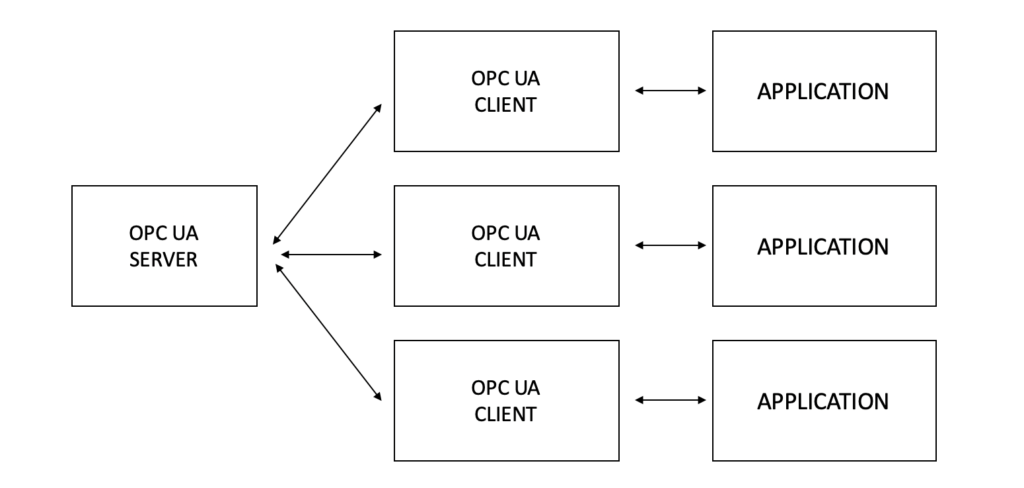

OPC UA is a reliable protocol for exchanging data between the applications in levels 1-4 on the edge, working in a synchronous, point-point, client-server architecture. With the DCS/PLC acting as an OPC server and the consuming applications act as OPC clients, this architecture has been designed and proven for data exchange among a limited number of applications on the edge – such as Historian, MES, and ERP.

Recent Industry 4.0 and IIoT trends spurred by cloud computing, analytics, human-machine interfaces have enabled newer and more efficient ways of solving problems in asset utilization, equipment monitoring, safety/health, and predictive maintenance. These solutions often require data exchange among many microservice applications distributed across on-premises and multi-cloud environments.

As the requirements for Industry 4.0 and IIoT enterprises evolve, the tight coupling and synchronous polling architecture of OPC UA impacts the performance of the source PLC/DCS systems, which are otherwise designed for process control. Additionally, OPC client licenses are expensive and priced at the server/client level, presenting financial, maintenance, and administrative challenges for integrating large numbers of consuming applications on the edge or in the cloud.

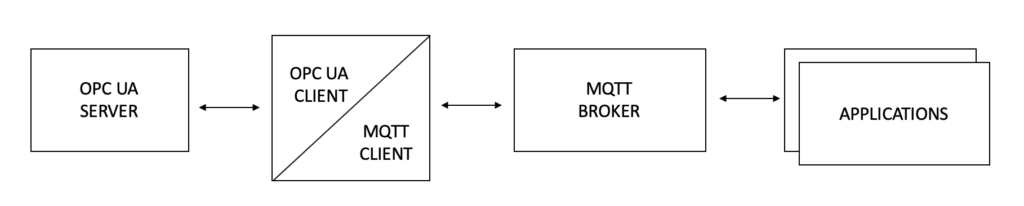

Decoupling OPC UA from Consuming Applications on the Edge and Cloud

Decoupling the OPC UA server from the consuming client applications is a simpler and more scalable way of moving sensor data from manufacturing plant to cloud and other edge applications. In the example below, an OPC UA client is ‘event-enabled’ by bridging the OPC stream to an MQTT Gateway, publishing sensor event streams to a network of event brokers – also known as an event mesh.

What is an Event Mesh?

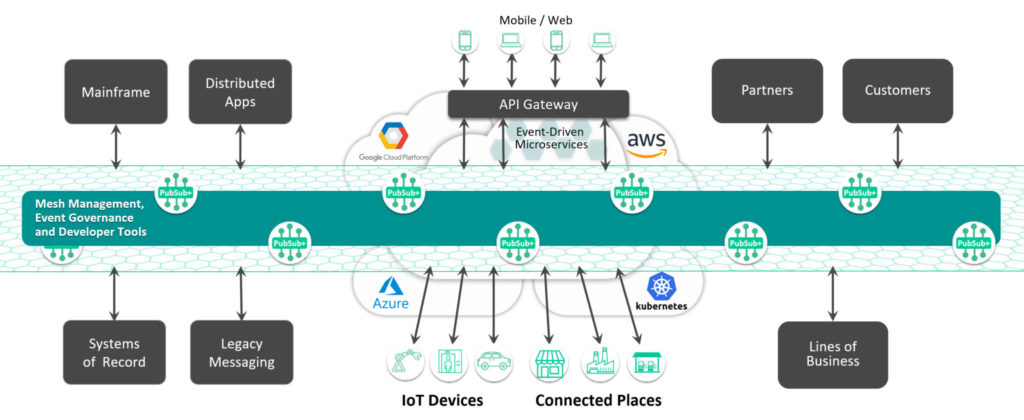

An event mesh is an architecture layer that streams data from one application to any other application or device, anywhere in the world. An event mesh is composed of a network of event brokers, that can be deployed across diverse cloud, on-premises and IoT environments.

An event mesh can be made up of Solace PubSub+ Event Brokers, as seen here.

With an event mesh in place, the PLC/DCS data doesn’t have to be integrated in a bespoke point-to-point manner with each of the consuming applications. Instead, it can fan-out sensor OPC event streams via an OPC UA-MQTT gateway into an event broker. PubSub+ Event Broker can make process control data available asynchronously to a large number of consuming applications in a decoupled way across the event mesh.

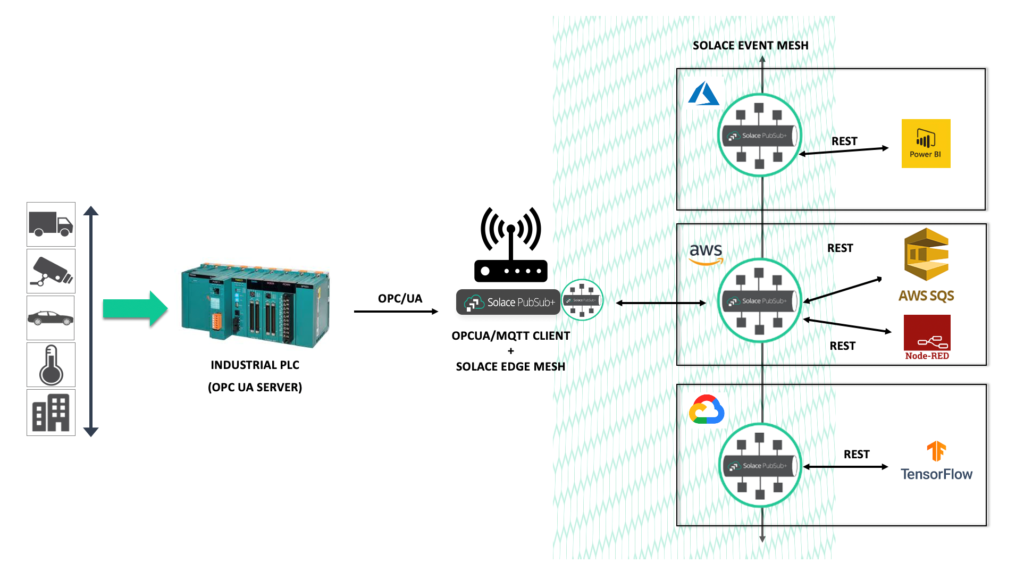

In the illustration below, the PLC publishes sensor streams over OPC UA to an edge gateway where OPC UA streams are converted to MQTT streams which are published to a Solace edge broker. The edge broker is bridged into a larger event mesh made up of PubSub+ Event Brokers deployed on multiple public and partner clouds.

In this example, the consuming applications are distributed in the three public clouds – Power BI on Azure Cloud, Tensor Flow ML on Google Cloud and Node Red, SQS on AWS Cloud.

For more details on Solace bridges and dynamic message routing, visit this page.

The Value of Adopting an Event Mesh for Efficient Industry 4.0 and IIoT Data Distribution

As stated, adopting an event mesh of Solace PubSub+ Event Brokers will result in efficient data distribution on all ISA-95 levels in the edges as well as in cloud environments. Event-enabling the OPC UA client through an OPC UA/MQTT gateway to an event broker effectively decouples applications, avoiding point-to-point connectivity between applications. Instead, data is published to a topic where any interested edge application can consume the IIoT data through dynamic routing and guaranteed sensor data delivery.

This architecture eliminates data bottlenecks and enables IIoT data ingest seamlessly at the edge across levels 1-4 and also external and partner cloud applications. The loose coupling, asynchronous and event-enabled integration lends itself for an extensible, reliable framework that makes for seamless and cost-effective operations.

Conclusion

Engaging early in the lifecycle of OT/IT architectures with standards bodies, specification working groups and PLC/DCS/SCADA vendors, Solace leads and influences OT standards and specifications such as O-PAS, SparkPlug, etc. to evolve a truly interoperable event-driven architecture on the edge for a more robust MQTT event payload, namespace and state management.

My colleagues and I will be publishing a series of blog posts about ways of improving the efficiency and scalability of data distribution in Industry 4.0 and IIoT, and about how to overcome challenges such as OT/IT convergence, ERP modernization and digital transformation as a whole. Stay tuned for the next piece on distributing IIoT data in edge and cloud from disparate devices via disparate protocols.

Vats Vanamamalai

Vats Vanamamalai