Read the post in 보도 자료 읽기

Artificial intelligence (AI) is transforming the manufacturing industry and its processes, paving the way for the evolution of smart factories.

“The smart factory is a flexible system that can self-optimize performance across a broader network, self-adapt to and learn from new conditions in real or near-real time, and autonomously run entire production processes.”1

A smart factory requires AI-based systems that take advantage of real-time data and can use it to learn, optimize, and make predictions, with the end-goal of maximizing overall equipment effectiveness (OEE). There are a few ways to maximize OEE across manufacturing plants and production operations, but gathering real-time Industrial Internet of Things (IIoT) data is paramount for the new frontier of industry 4.0 and smart factories.

Developing or upgrading a system with event-driven architecture as the foundation is the best way to get real-time data to AI systems for analysis and modeling. It requires integrated and connected IT and OT ecosystems to automate manufacturing operations, including across the supply chain.

Digital Manufacturing Platforms for Connected Smart Factories: Signe-S and Event Mesh

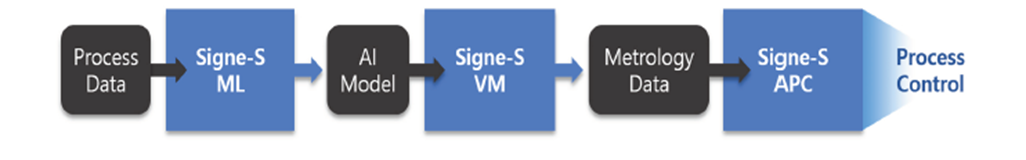

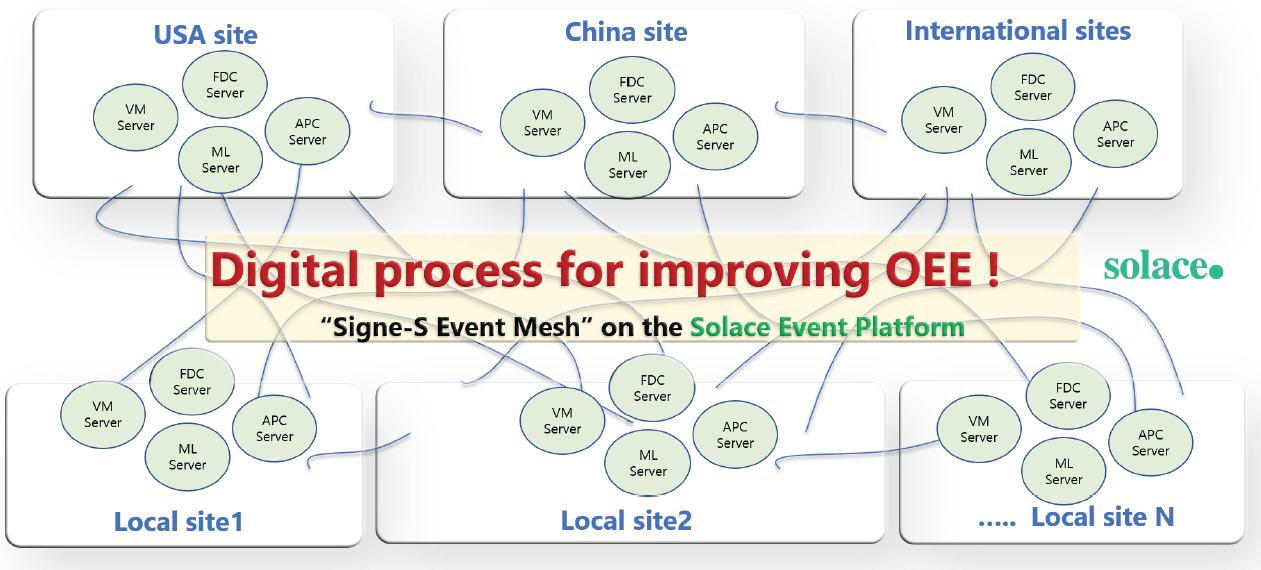

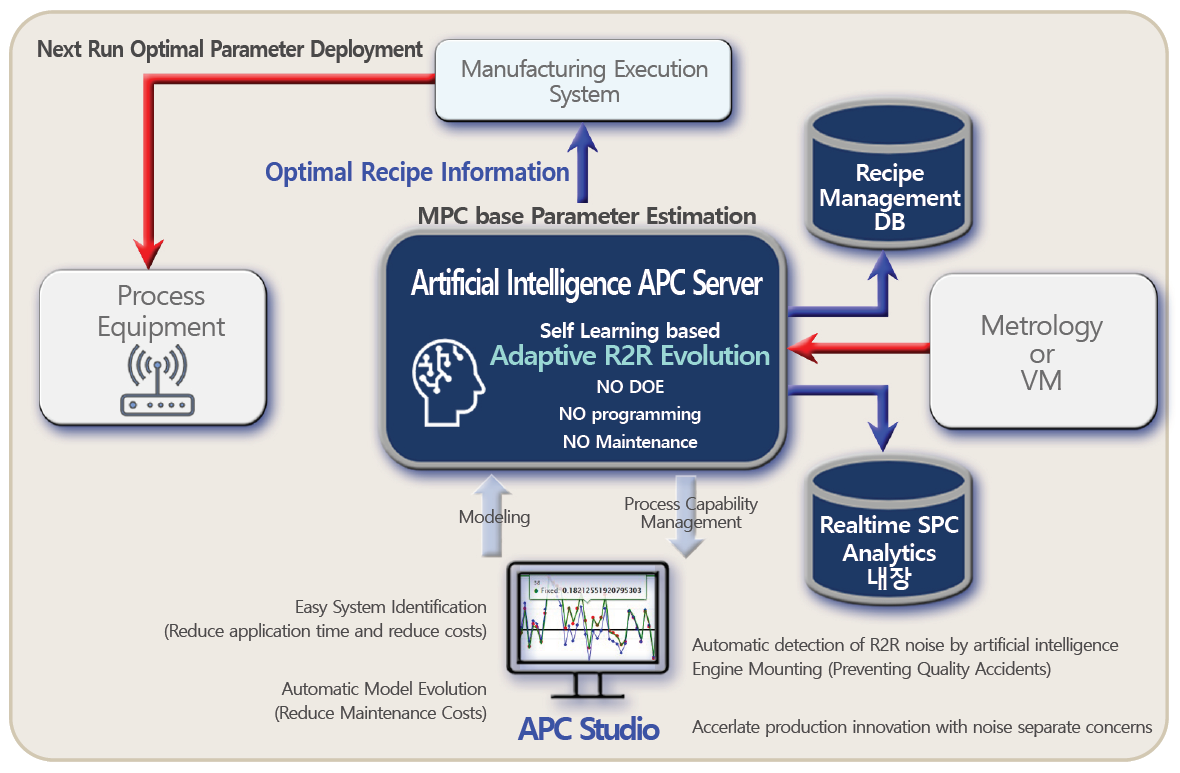

Data Science & Engineering for Yield (DSEY) has developed an intelligent smart factory software and partnered with Solace to create a real-time data network called an event mesh. The Signe-S framework includes components for machine learning (Signe-S ML), virtual metrology (Signe-S VM), and advanced process control (Signe-S APC) which work together to maximize a plant’s OEE.

The benefits of this event-driven system include:

- Application of machine learning with no coding

- Real-time process prediction and control

- Self-learning machine learning algorithms

- Quick modeling

- Results from various perspectives

An event mesh provides the means to dynamically distribute data (in the form of events) from IoT devices or applications to other manufacturing systems and applications that require the information to perform their functions, no matter where they are deployed (on-premises, in the cloud, etc.).

Through event-driven architecture, a smart factory can be automated, analyze inefficiencies between multiple production lines and global locations, and predict downtime due to mechanical failures, supply chain issues, or logistics delays. With Signe-S and an event mesh, relevant events are communicated to processes and equipment in real-time so AI-based decisions and machine learning can be implemented.

This digital manufacturing platform leverages real-time connectivity to create a smart factory that is agile, adaptive, and intelligent.

Smart Factory Machine Learning with No Coding

Smart factories go beyond automation; they adapt and learn in real-time and optimize production processes — often on a global scale. Machine learning enables smart factories to ingest, interpret, and adapt to real-time data from connected equipment. Big data analysis and machine learning modeling can be time-consuming and costly. DSEY’s Signe-S ML product removes the trial and error aspect of data analysis and enables machine learning with a click of the mouse instead of complex coding. It has automated machine learning capabilities built-in, which have been optimized for the characteristics of manufacturing sites (pre-processing, data analysis, and engineering algorithms).

Real-Time Process Performance Predictions

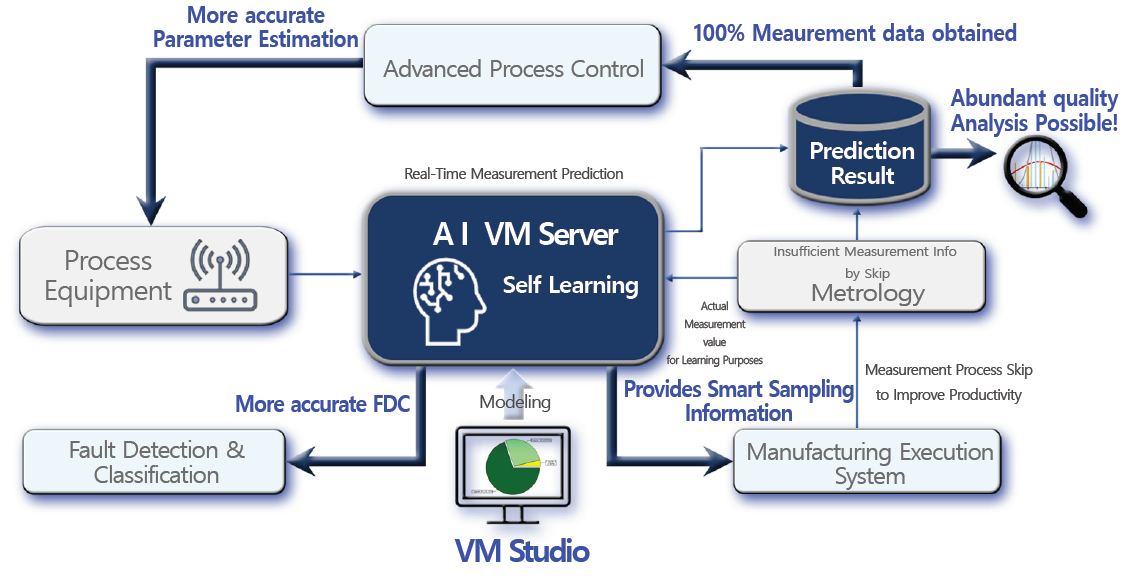

By employing mathematical models, quality control can be enhanced to predict product quality drifts without conducting physical measurements. With the overarching goal in manufacturing of reducing OEE, quality control is a large component because product flaws can result in downtime. Virtual metrology is the method by which smart factories can predict variations and secure 100% control over quality activities. The challenge of virtual metrology systems is accurate prediction algorithms.

DSEY’s Signe-S VM is a self-learning based virtual measurement solution that makes predictions based on AI machine learning models while monitoring its own accuracy in real-time and processing maintenance tasks (which then “re-learn” with AI). Signe-S VM is optimized for manufacturing sites to solve frequent modeling issues from product/process changes and field noise problems, which are the main weaknesses of existing virtual measurement systems.

When used in combination with fault detection and classification (FDC), Signe-S VM can improve Run to Run Control (R2R) and further reduce manufacturing costs by reducing false determination.

Smart factories making use of DSEY’s virtual metrology solution receive the benefits of:

- Real-time prediction & discrimination of future measurements

- Automatic sensors to process changes

- AI-based recommendations of measurement samplings to maximize productivity

- Resolution of conventional FDC’s congenital problems with accuracy

- Dramatically enhanced R2R applications

- Rich measurement data for quality analysis

The Evolution of Advanced Process Control in Smart Factories

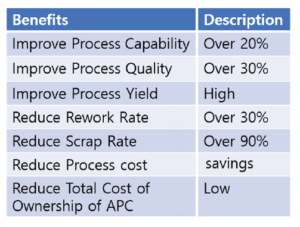

Advanced process control (APC) is not new, but the reliability and intelligence behind APC systems is drastically improving. For model-based APC software to be useful, it must accurately represent process dynamics and operations. The role of process management is another key factor that affects OEE, and Signe-S APC is equipped with advanced control algorithms that can perform parameter estimates and provide optimal process conditions in real-time.

The total cost of ownership of existing R2R systems can be reduced through Signe-S APC’s self-learning capabilities and auto-evolution without manually modifying programs or conducting software maintenance when a process changes. Since Signe-S APC evolves intelligently, it enables seamless and accurate process control even in changing processes, significantly reducing quality costs, process engineering, and R2R maintenance.

Conclusion

With evolving technical capabilities and advances in AI, smart factories are becoming viable options for manufacturers to accelerate their productions and lower their costs. Digital technologies such as event mesh and AI-based equipment like Signe-S provide powerful capabilities to manufacturers looking to modernize their processes and take advantage of intelligent systems that effectively eliminate human intervention.

Aligning IT and OT systems is making it possible for manufacturers to eliminate inefficiencies and make enterprise-wide decisions instead of plant-level decisions. Systems, processes, and applications having access to real-time data is crucial to a smart factory’s quality management, operating cost, sustainability – all things that drive OEE.

Implementing an intelligent digital manufacturing platform that detects, predicts, adapts, and controls process quality in real-time is how smart factory leaders can evolve their operations and differentiate themselves from the competition.

References:

- Rick Burke, Adam Mussomeli, Stephen Laaper, Martin Hartigan, Brenna Sniderman. “The smart factory.” Deloitte Insights. https://www2.deloitte.com/us/en/insights/focus/industry-4-0/smart-factory-connected-manufacturing.html# Accessed 1 December 2020.

- Shiama Tilouche, Samuel Bassetto, Vahid Parvoti Nia. “Classification Algorithms for Virtual Metrology“ http://www.mgi.polymtl.ca/Samuel.Bassetto/papers/ICMIT2014.pdf Accessed 1 December 2020

About the Author

Explore other posts from category: Use Cases

Deasoo Han (Guest Author)

Deasoo Han (Guest Author)