The industrial internet of things (IIoT) is transforming the manufacturing process by enabling manufacturers to collect and analyze large amounts of data from their machines, sensors, and other devices in their production lines on factory floors. According to Grand View Research, the global IIoT market size was valued at USD 321.81 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 23.2% from 2023 to 2030. The growth of this market hinges on the collection of data that is being driven by IIoT.

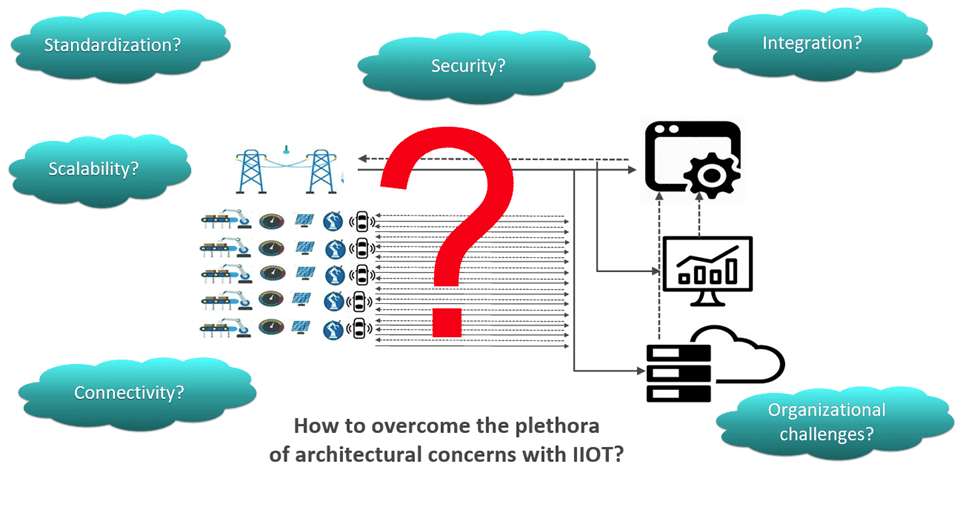

Challenges in Implementing IIoT

As manufacturers take strides toward IIoT, there are several reasons why it can be challenging for them to collect data from and interact with equipment:

- Lack of standardization – There is a lack of standardization in the types of equipment used in manufacturing, as well as the data formats generated by these devices.

- Connectivity issues – many pieces of manufacturing equipment, especially legacy equipment, are not designed to be connected to a network, making it difficult to collect data; even when equipment is connected, there may be issues with signal strength, interference, or network protocol compatibility.

- Security concerns – need to collect and analyze data from equipment without compromising the security of operations or exposing sensitive information to unauthorized parties.

- Integration challenges – collecting and analyzing data from manufacturing equipment may require integrating data from multiple sources including ERP systems, SCADA systems, and other software applications.

- Organizational challenges – there needs to be a collaborative environment between information technology (IT) and operational technology (OT) teams to ingest data in the field and process it at scale.

- Scalability challenges – dealing with thousands of IoT devices means handling an enormous amount of data. Moving this enormous amount of data at scale requires a lot of planning.

Figure 1: Challenges in IIOT

To meet Industry 4.0 requirements, manufacturers must create a more connected, efficient, and intelligent manufacturing ecosystem by leveraging advanced technologies. Enterprise applications need to interact with edge equipment proactively and in real-time. This requires an architectural paradigm shift to event-driven architecture.

The Solution – EDA with MQTT Broker And Edge Processing

Enter the MQTT Protocol and MQTT Broker

MQTT is an OASIS standard messaging protocol for the internet of things (IoT). It is designed as an extremely lightweight publish/subscribe messaging transport that is ideal for connecting remote devices with a small code footprint and minimal network bandwidth.

MQTT has become a de facto standard for sending data from edge devices to IT systems. Thus, MQTT brokers (which understand MQTT protocol) play a critical role in the functioning of MQTT-based communication systems, enabling the efficient and reliable exchange of data between devices and applications.

Having a scalable MQTT broker ensures resilient communication between IT and OT systems, so when choosing an MQTT broker, it’s essential for manufacturers to consider factors such as scalability, performance, reliability, security, and ease of use, depending on the specific needs of the use case.

Solace Event Broker is a full-featured event broker with built-in support for MQTT which can scale up to millions of connections while also keeping up with the performance with high throughput and low latency. Solace Event Broker also offer geographical scaling and dynamic message routing capabilities, which allow for the broad distribution of real-time messages to any geographical location. Solace Event Broker also works well with the edge platform which is increasingly becoming important for edge computing use cases.

Edge Platform: The ‘Eyes and Ears’ of Industry 4.0

A robust edge computing platform can help companies on the road to Industry 4.0 in multiple ways as described below:

- Connecting OT systems with IT systems, enabling data to be collected from OT devices, processed at the edge of the network, and transmitted to IT systems for analysis and decision-making over an MQTT broker.

- Wiring up OT systems to IT systems using an edge infrastructure platform by:

- Connecting OT devices – The first step is connecting the OT devices to the edge infrastructure platform. This involves installing sensors, controllers, and other devices that can communicate with the edge platform.

- Installing edge devices – Once the OT devices are connected, edge devices such as gateways and routers are installed. These devices act as intermediaries between the OT devices and the IT systems, processing data at the edge of the network and forwarding it to the IT systems.

- Configuring edge platform – The edge infrastructure platform is then configured to receive and process data from the OT devices. This involves setting up data collection and storage, data analytics, and security protocols.

- Connecting to IT systems – The final step is connecting the edge platform to the IT systems. This may involve setting up a secure connection, configuring data transfer protocols, and integrating the data into the IT systems.

- Optimizing this OT/IT integration with edge computing efficiencies like:

- SparkPlugB – This messaging protocol is designed for IIoT applications and provides a standardized, secure, and efficient way for devices and applications to communicate with each other. It also allows to cluster things and just send the updated values (summarize).

- Edge Compute processing – Process as much data as possible at the edge.

- Digital Twins – These are virtual replicas of physical assets, systems, or processes that are created and maintained through the use of digital technologies such as sensors, IoT devices, artificial intelligence (AI), and machine learning (ML); their purpose is to provide a digital representation of a physical entity in order to optimize its performance, improve its maintenance and reduce downtime, and enable simulation of potential scenarios for testing and analysis; allows manufacturers to:

- Simulate in the cloud and deploy to edge devices all the data flows.

- Exchange state and data between physical and digital twin is made over MQTT.

- Combining with enterprise applications like SCADA, MES and ERP systems.

Edge Signal is an edge computing platform built to handle all technological and organizational complexities of edge device and application management. The platform manages a highly distributed variety of hardware via a single dashboard from rich IoT and cloud integration options, management, monitoring, run-time-environment, software updates, and security perspectives. It also provides different integration use case such as no-low, low-code to highly customized App code.

Edge Signal and Solace Event Broker Joint Architecture

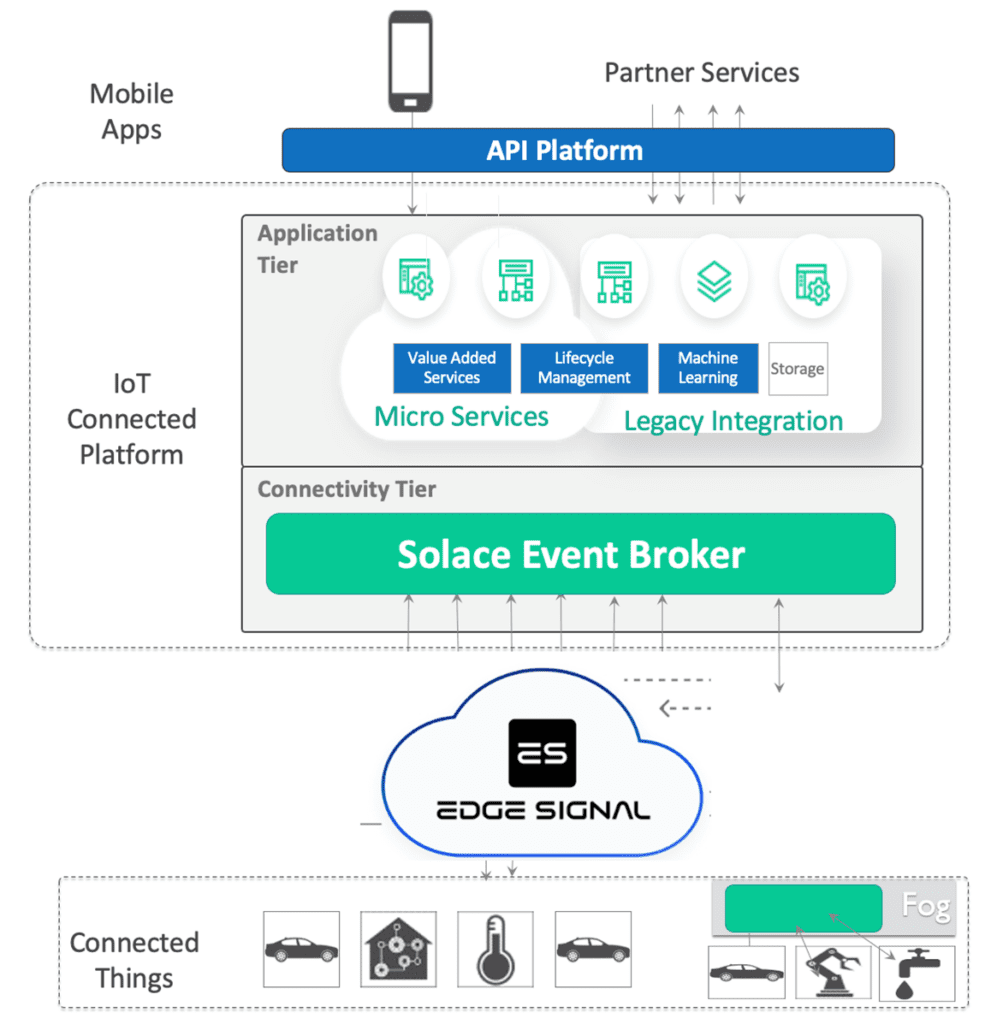

As you’ve seen earlier, Solace Event Broker and Edge Signal individually can provide a vast advantage to overall IIoT architecture. A joint architecture with these two components will prove to be the gold standard.

Together, Edge Signal and Solace Event Broker will become essential components for modern manufacturers who want to build connected and intelligent factories and leverage the benefits of Industry 4.0 technologies.

The combined solution can help enhance the performance, security, and scalability of, as well as enable the architecture to handle large volumes of data from, multiple devices and applications.

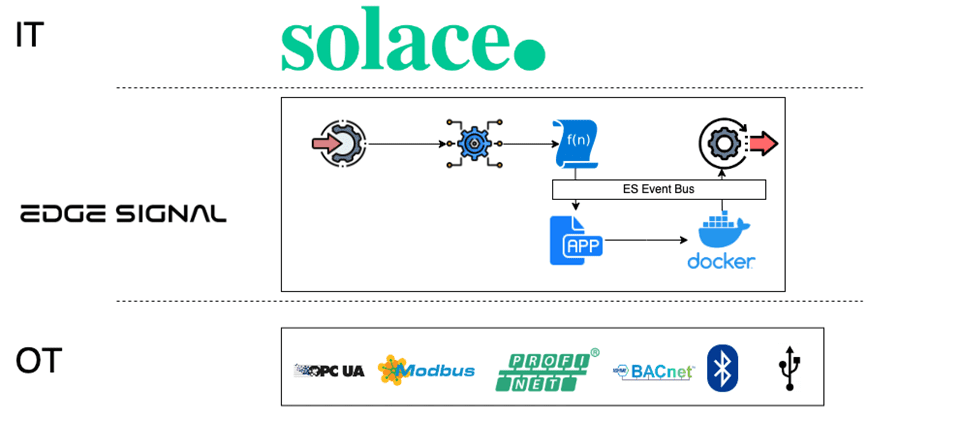

The architectural diagram below shows this integrated solution.

Figure 2: High-level architecture of Solace and Edge Signal

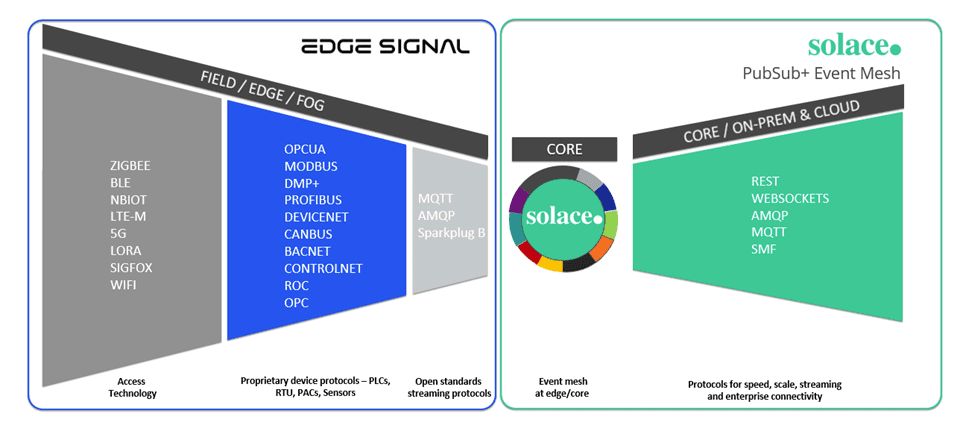

Protocol Support

The combined architecture provides a wide variety of protocol options for enterprises to choose from. The Solace broker also gives flexibility for protocol interoperability which means that devices can use the MQTT protocol (or other proprietary IoT protocols) and applications can subscribe to the same message using other application-specific protocol such as JMS, AMQP, etc. Solace broker will do the protocol translation.

The below diagram gives the list of all the protocols supported by Edge Signal and Solace Event Broker:

Figure 3: Protocol stack of Solace and Edge Signal.

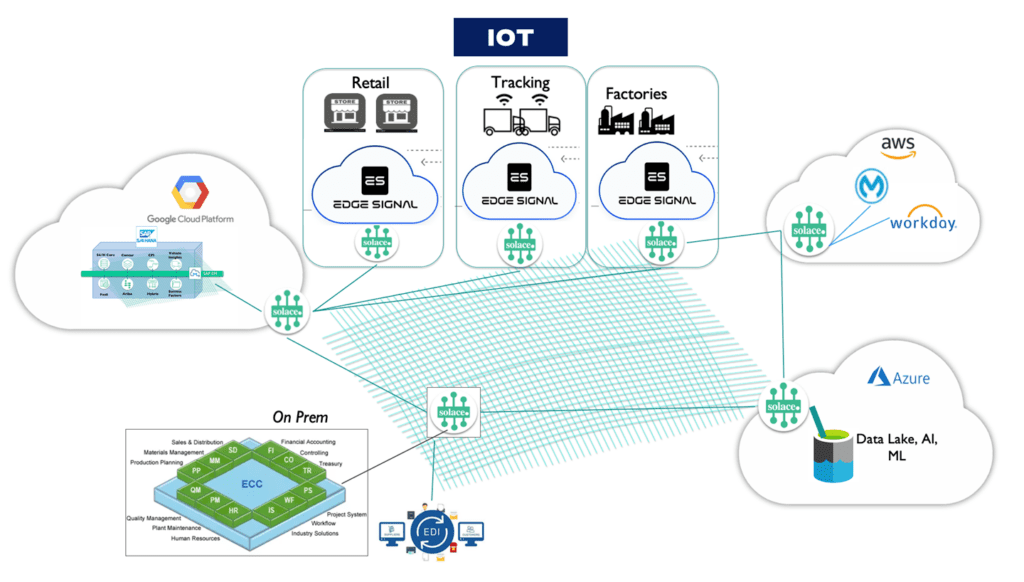

Event Mesh Capability

Solace Event Broker has multiple capabilities which will simplify the overall architecture. The broker’s event mesh capabilities will help bring the OT and IT data together. By enabling communication and integration between IT and OT systems, an event mesh can help to improve the efficiency and effectiveness of an enterprise. Through Event Mesh Applications, people and systems will have access to real-time data where it is needed and when it is needed.

Figure 4: Event Mesh Capability

Edge Signal Operations

Edge Signal can support 3 different kinds of use cases:

- No-code: Customers use out-of-the-box integrations to send data to the cloud and other enterprise applications. They can also optionally run basic out-of-the-box filtering and data transformation capabilities.

- Low-code: On top of no-code, customers can also modify and transform the events by using inline functions.

- App-code: If a customer has a compute-heavy need like AI/ML use cases, our SDK and event bus supports integrating native or containerized applications to low-code/no-code integrations. A typical scenario is receiving image frames from IP cameras and inferring an AI model on the images. After you detect an event or classify an object, you can send this to the cloud. In order to implement this, you just use Edge Signal’s integrations and focus on your own AI application without the worry of fetching the data or transferring it.

The diagram below illustrates how low-code, no-code, and app-code scenarios can run together on a Linux device managed by Edge Signal.

Figure 5: EdgeSignal Use Cases

Conclusion

Embarking on an IIoT project for any manufacturing/industrial enterprise is becoming a necessity. Solace Event Broker and Edge Signal have helped many organizations take care of scalability, security, and a multitude of concerns that come with integrating OT and IT. This has also allowed these companies to concentrate on their core business logic while we take care of their integration woes.

I’d love to talk to you regarding your IIoT journey and how we can be of help.

For more information, please visit us on solace.com or edgesignal.io

Explore other posts from categories: For Architects | For Developers

Neha Sinha

Neha Sinha