Modern manufacturing demands the real-time movement of information across every environment and component of the digital enterprise, but integrating IT and OT across plants, datacenters, clouds and geographies is no small feat. Solace helps you manage it all.

- Move real-time operational data between machines, productions lines and sites

- Enable event-driven communications across cloud, on-prem and edge environments

- Ensure secure, reliable, predictable communications across OT and IT systems

- Elastically scale your system to manage millions of devices and billions of real-time events

What can manufacturers do with Solace?

Supply Chain Improve Resilience of Global Supply Chains

Volatile markets and shifting trade routes cause supply chain disruptions that require fast, insightful, well-coordinated responses.

With Solace, you can eliminate blind spots in material flow and shipment status by continuously streaming data between carriers, suppliers, warehouses and your ERP systems.

This enables proactive decision-making and rapid responses that minimize costly disruptions and keeps goods moving efficiently.

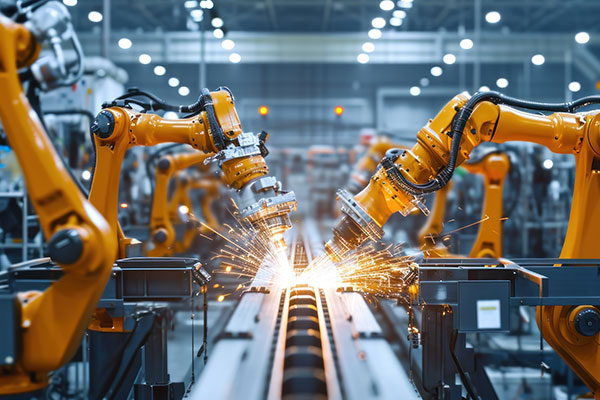

Industry 4.0 Digitize Manufacturing for More Intelligent, Real-Time Factory Operations and Line Performance

Manufacturing operations depend on fast, accurate visibility across OT and IT systems, from the plant floor to enterprise applications.

By letting PLCs, SCADA systems, MES, industrial data historians and business applications share information in real-time, Solace can help you more effectively monitor operations, optimize performance and throughput, and reduce downtime across production lines and sites.

Servitization Transform Products into Connected Services Focused on Outcome

Manufacturers are evolving beyond one-time product sales toward recurring, service-oriented models. Solace enables this shift by streaming real-time equipment, usage, and maintenance data that powers pay-per-use and outcome-based offerings.

With every event shared instantly between customers, devices, and providers, Solace can help you deliver personalized experiences, predictable revenue, and stronger long-term customer relationships.

Augmenting and Enabling Talent Combine AI, Automation, and Human Expertise

Labor shortages and rising costs are driving manufacturers to adopt connected worker platforms and use agentic AI to help operators, technicians and engineers do their jobs.

Solace helps you create a workforce where autonomous agents and human operators work together more safely and efficiently by giving AI agents the real-time operational context they need, and routing recommendations back to automation systems and human workers via HMIs and mobile apps.

Some Manufacturing Success Stories

FREE WHITEPAPER

Executive Guide to Adding Automation and Intelligence to Your Manufacturing Operations

Read the free guide to learn…

- Why real-time data and EDA are critical to powering agentic AI in manufacturing

- Where AI agents drive the most immediate operational impact for manufacturers

- How to get started without overhauling your entire platform.

4 Ways an Event Mesh Supports Digital Manufacturing Transformation

. For large manufacturers with diverse technologies and value chains distributed across the globe, an event mesh can be the common data dial tone ensuring that events are routed from where they are created to where they need to be.

How an Event Mesh Enables Digital Transformation in Manufacturing

Learn how the alignment of IT and OT makes it possible to give systems, processes, and applications access to real-time data and improve a smart factory’s quality management, operating cost, sustainability – all things that drive OEE.