As the VP of Technology for TELUS Agriculture & Consumer Goods, I’m always looking for ways to optimize the complex supply chain that gets goods from those who produce them to end users.

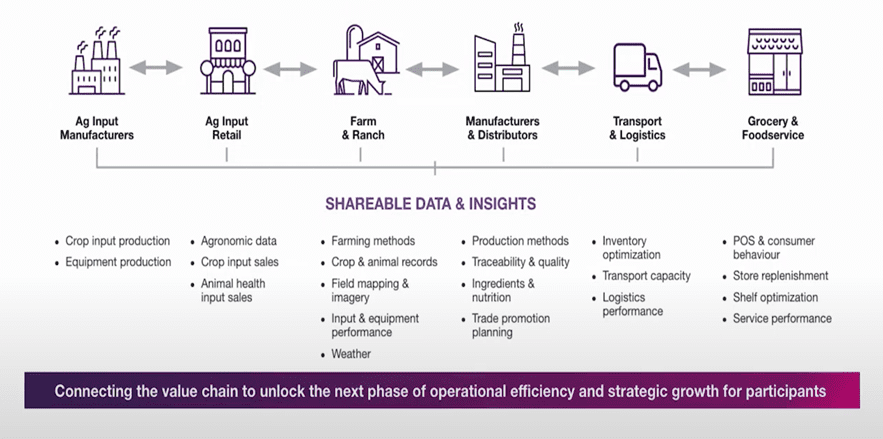

Our company’s mission is to create the best producer-to-consumer outcomes, and it’s with that goal in mind that we focus our digital transformation efforts on employing technology to deliver timely insights that inform and empower producers, manufacturers, and retailers around the world to improve the quality, safety, distribution, and sustainability of food and consumer goods.

The agriculture industry tends to lag behind others when it comes to technology adoption, so we have our work cut out for us. Our four-pronged digital transformation strategy reflects that, we:

- Connect a rural world that’s underserved in terms of communications capabilities. That includes leveraging new 5G networks and connecting IoT devices in the field.

- Digitize key information to empower all parties, because while there are pockets of excellence, there are still processes that remain manual, time consuming and labor intensive.

- Optimize our customers’ operations through data insights and artificial intelligence, i.e., helping them gain insights into their business. This is critical because the supply chain in agriculture is one of the most fragmented of any industry.

- Exchange digitized information to help all parties operate more efficiently. Basically, we need to be able to get them working together in a more real-time manner, more instant gratification if you will, of the data.

Between the short life span of perishable products and seasonality of agricultural products, we need information about things that happen to these products (or “events” as we call them) to be more real-time in order to enable faster business response.

To achieve that goal, we’ve built a platform for supply chain optimization that underpins everything we do. It’s called the TELUS Agricultural Data Exchange platform, or ADX, and can be seen underpinning everything in the diagram below.

Source: EDA Summit

The integration here is quite complicated. I’d argue that there’s more data in agriculture than probably any other industry, and unfortunately, it’s also very dirty – requiring a lot of work to make it valuable.

It’s the integration of all these processes, people and data points that led us towards embracing event-driven architecture (EDA) – a software paradigm exploding amongst leaders in real-time digital transformation. We also needed to rely on technology like that of Solace’s EDA platform to help us connect all of these data inputs and support our transition to becoming an event-driven organization.

While ADX is still in its infancy, we’re already putting it to good use. Here’s how:

IoT is huge for us right now. We recently went live with our TELUS Cold Chain Management solution, which is a favorite of mine as it’s tangible and has the potential for improving the global chronic food waste challenge.

For those unfamiliar, cold chain refers to monitoring the temperature of perishable products in order to maintain quality and safety through each link – from the point of origin, through the distribution chain.

Our cold chain solution helps producers mitigate the potential temperature abuse occurring throughout transportation. A terrific example recently was with a large customer in Australia who was losing two days of shelf life on strawberries. They piloted our Cold Chain Management solution to get some insight into potential breaches in temperature during transit, and it was found that truck drivers were putting their trucks into eco mode during the 12+ hour drive to improve fuel economy, which led to the refrigerated containers warming up. Upon arriving at the distribution center, drivers would fire the engine back up, turn the freezer all the way back down, and would pass the temperature check at the receiving end. The strawberries were basically frozen at the back of the truck, while at the doors, they were just coming to the right temperature.

The strawberries were being damaged and shelf life was impacted. This was determined by implementing a record of temperature measurement events that now flags both high and low temperature extremes for corrective action to take place.

None of this could have occurred without real-time temperature measures, notifications of breaches and continuous improvement without the underlying digital backbone of the TELUS ADX and Solace PubSub+ EDA platforms.

You can hear more about this example in my recent EDA Summit 2022 keynote presentation: Enabling More Efficient Production with EDA. Meanwhile, if you have any questions about implementing cold chain management, real-time supply chain optimization or perhaps TELUS’ foray into event-driven architecture, follow and connect with me on LinkedIn or check out our website.

About the Author

Explore other posts from category: Use Cases

Jeff Bradshaw

Jeff Bradshaw