Subscribe to Our Blog

Get the latest trends, solutions, and insights into the event-driven future every week.

Thanks for subscribing.

One of the world’s biggest consumer packaged goods (CPG) companies believes digital innovation and transformation is the key to continuing to satisfy the billions of people who use their products every day. A critical success factor for of those efforts – the speed with which they distribute information.

That’s why they built an event mesh, a network of event brokers that enables real-time data movement between diverse applications and devices across geographies and environments. It efficiently streams information between applications, sensors, control systems and people around the world, both within their organization and across their massive network of suppliers, transportation and logistics service providers, brands, retailers, and wholesalers.

This event mesh has given application teams around the world the ability to build applications that create new value by publishing and/or subscribing to real-time data streams.

What is Real-Time Visibility in Supply Chain and How Does EDA Help?

Event-driven architecture (EDA) is a different way of thinking about distributed systems like supply chain management systems. Event-driven architecture is recommended by analysts, such as Gartner, as the most efficient way of dealing with the never-ending myriad of exceptions and events that disrupt supply chains. Most legacy solutions rely on point-to-point request/reply interactions, meaning you would poll the vessel management service (often a SaaS such as ClearMetal or OceanIT) to check the status of a shipment.

In supply chain systems built with event-driven architecture, information about events like a change in location or rejection of papers is immediately “published” to an event broker with a topic that indicates what it’s about. The event broker then delivers that information to every application that has “subscribed” to receive events with that topic. This leads to faster data delivery, obviously, and a loosely coupled architecture where applications are not directly tied to each other.

How the Virtual Ocean Control Tower Improves Supply Chain Visibility

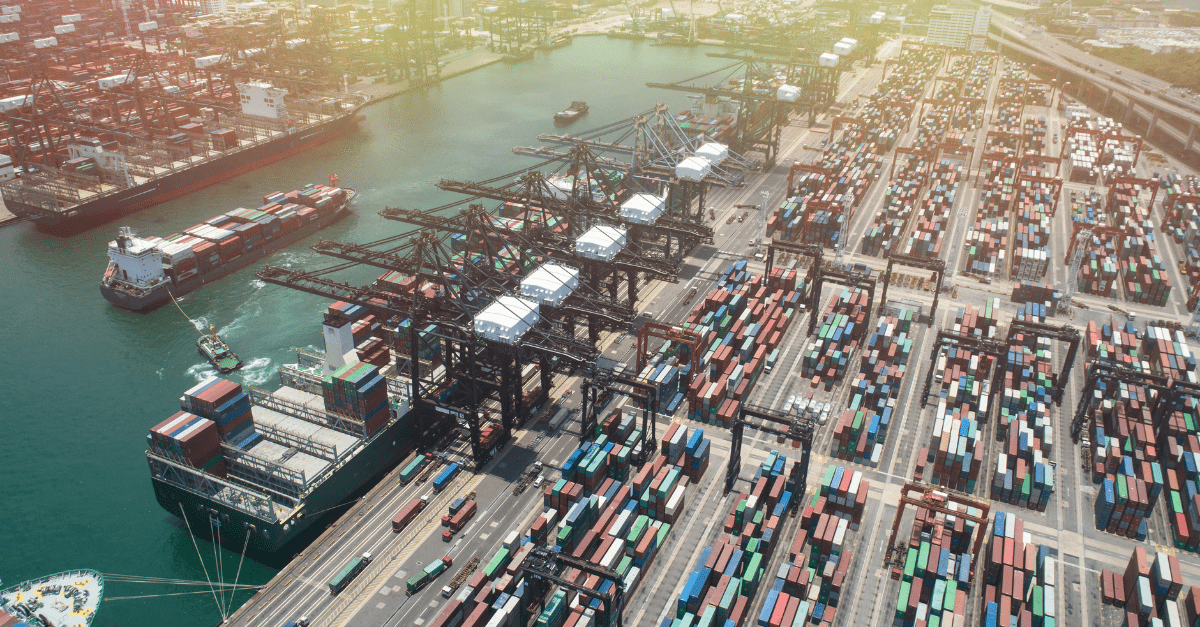

Back to the CPG company at hand, as an example of how to improve supply chain visibility, slow shipment processing was delaying the delivery of goods, and resulting in high demurrage and detention charges. (Both being fees that shipping companies charge for the time it takes to unload and then return empty containers after they’ve arrived in port.)

The main cause? They lacked real-time visibility into the movement of ships and cargo.

They decided to build an application to speed up customs processing at ports, which they called Virtual Ocean Control Tower. Their goal was to achieve real-time visibility into their sea freight operations, while improving sustainability across the ocean shipping industry.

Their Virtual Ocean Control Tower connects dozens of shipping lines and uses satellite data to track thousands of vessels travelling between hundreds of ports, as well as hundreds of material suppliers. The types of data collect includes:

- Vessel position

- Container logistics

- Port congestion

- CO2 emission alerts

That information flow, which is enabled by an event mesh, empowers different applications and users with relevant and time-sensitive information that may impact the delivery their shipments.

These events are sent to and consumed by a variety of subscribers, including the Virtual Ocean Control Tower dashboard, which synthesizes the information into an interactive Google map that is refreshed every 30 minutes.

By giving users a more up-to-date understanding of where ships are, how fast they are moving, which ports are backed up, etc., Virtual Ocean Control Tower enables them to better predict and more proactively address situations and risks, instead of always reacting to events after they have impacted their operations.

These data points and ensuing supply chain analytics have helped them improve efficiency, ensure safety, and reduce environmental impact by optimizing:

- Vessel speed

- Navigation

- Arrival and departure times

- Sustainability via actionable real-time CO2 alerts

- The offloading of containers, which has reduced demurrage and detention charges by over $10M dollars.

To learn more, watch this 20-minute EDA Summit talk in which Unilever’s IT team leads, Kartheek Thummala and Pranav Mohanpurkar explain the business problem that drove the need for Virtual Ocean Control Tower, the technical challenges they faced, and how event-driven architecture and an event mesh helped them achieve their goals.

Building Beyond the Success of Virtual Ocean Control Tower

In September, our Chief Technology Solutions Officer Sumeet Puri teamed up with Sushil Sarda, lead manager at Unilever, to present a talk entitled Meshing Around: Next Gen Agility and Responsiveness – Unilever’s EDA journey with Event Mesh.

Learn more about:

- The basics of event driven thinking

- Event mesh as a data movement backbone

- Event discovery and cataloging

- How Unilever is using an event mesh to disrupt and transform e-commerce

* * *

Unilever is working with several partners on the Virtual Ocean Control Tower. ClearMetal runs the technology platform, MarineTraffic provides the satellite data, Inttra’s booking platform links all our suppliers, the Dista AI-enabled location intelligence platform provides a live interactive marine dashboard hosted on Google Maps, and Solace choreographs all components and event streams.

Explore other posts from categories: For Architects | Use Cases

With over two decades of digital and product marketing leadership, Alecia currently oversees Solace's global marketing and enablement campaigns, and vertical product marketing initiatives.

Prior to her current role, Alecia worked as a growth and product marketing consultant to SaaS companies, in product marketing at Mitel and Halogen Software, and as Director of Marketing at dna13 (now Canada NewsWire). Originally from Australia, she holds a BA/BSc, and Masters in Marketing from Monash University, is a fanatic #PeletonMom, and thrives on helping other women advance their careers in high tech.

Subscribe to Our Blog

Get the latest trends, solutions, and insights into the event-driven future every week.

Thanks for subscribing.